Skilled toolmakers

Our team of engineers develops and designs the necessary tools and many other production resources in-house. After development, the tools are built by our highly experienced and skilled toolmakers.

Design & development

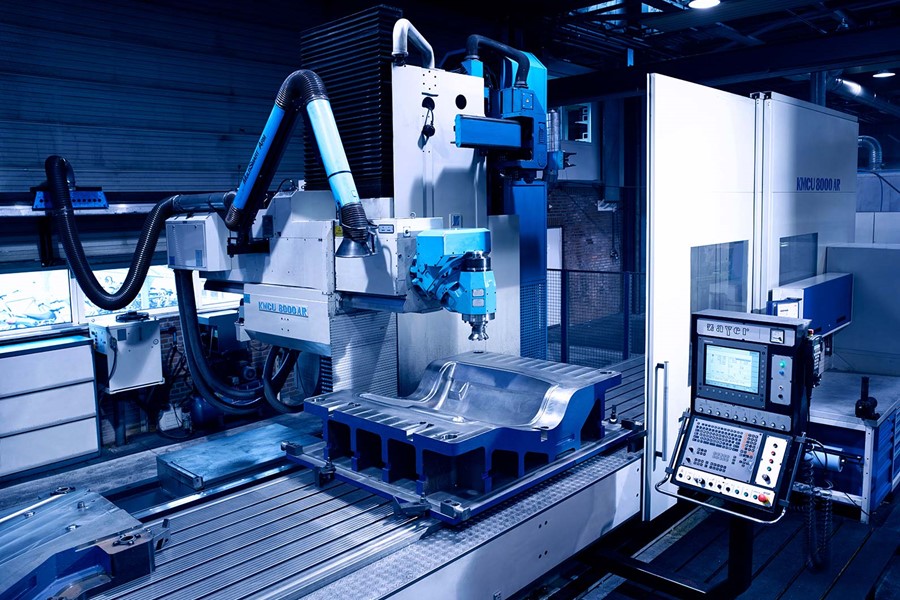

Toolshop

When a project is awarded to Witte van Moort, the engineering department designs the required tools using CAD-CAM software. We then produce the tools ourselves in our own tool shop, under the supervision of the engineering department of course. Based on our clear project planning, we will inform you, our customer, periodically about the progress. This includes the status of the various phases of the tooling project, including the delivery of a so-called 'first-out-of-tool' product, the first product produced by the tool set.

Specifications

Process and quality

While the tool is being built, we set out all the specifications required for serial production, in terms of product, process and quality. After the tool is released by engineering, we test each of these specifications during a 0-series. Any optimisations of the various specifications are incorporated, so that the process is prepared in detail and high-quality products can be made in series.

After your approval as the customer, the product is ready for serial production. Customer orders are processed through EDI. The various production steps are carefully planned to ensure the products are delivered to you just-in-time. The result is not only the highest quality but also come with a high delivery reliability.

Contact

Want to know more about tool development and production?

Please contact one of our advisors

Expertise

The right solution for each industry

Metalwork is custom work.From the machining of a flat plate of the production of semi-finished products, we offer solutions for various industries.